Vacuum powder feeding system

Key words:

Category:

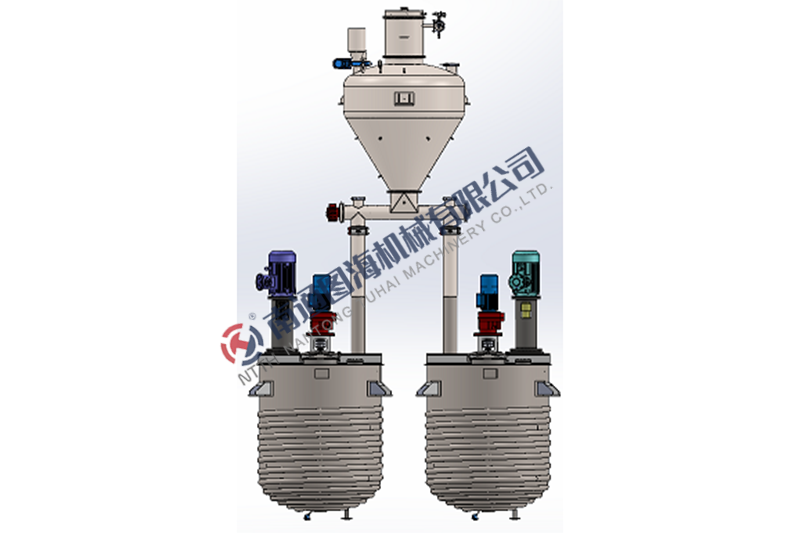

Product Description

constituent

Using the negative pressure air flow generated by the roots fan device, the material is sucked in from the feeding port, separated by the material gas separator in the vacuum feeder, clean air passes through the filter element, and is discharged into the atmosphere through the roots fan, and the material is separated into the buffer bin below, and when the feeding weight reaches the set value, the make-up valve opens, the unloading auger opens and runs, and the material is transported to the designated equipment; The blowback airbag automatically cleans the filter element to ensure efficient performance in the next cycle; Vibration and other auxiliary feeding device starting, auxiliary unloading; After unloading, it enters the suction state again.

Equipment highlights

●Using various automatic components, high degree of automation;

●The conveying adopts vacuum negative pressure conveying, which has a wide range of conveying forms and convenient conveying;

●Using precision filter bags, no spillage and no pollution;

●The discharger adopts twister frequency conversion speed regulation to achieve controllable discharge speed;

●Many places are equipped with gas discs and oscillators to achieve no material accumulation;

●Parameters such as suction time, discharge time, and backflushing times can be set freely;

●Automatic shutdown of full material, automatic opening of lack of material;

●PLC automatic control, original suction machine algorithm, stable, efficient and energy-saving;

●The operation process is carried out in a vacuum environment to avoid cross-contamination between materials and the outside world and operators;

●Strong conveying capacity, low energy consumption, good stability performance, small floor space, wide range of applications.

Introduction to the device

●According to the customer's demand for powder volume, to customize the volume of powder silo tank to achieve customer needs;

●According to the customer's demand powder speed, the fan with the appropriate air volume can be selected to achieve customer demand;

●According to the customer's site layout form, the appropriate scheme can be selected to achieve customer needs.

Suitable filler

|

Silicon powder |

Antimony trioxide |

zinc oxide |

|

alumina |

magnesium oxide |

Boron oxide |

|

Titanium dioxide |

baryta |

silicon carbide |

|

Silicon nitride |

Beryllium oxide |

calcium oxide |

Conveying method

List of parameters

| serial number | Model | Air pump power (KW) | Discharger power(KW) | Air pressure requirement (Mpa) | Conveying capacity(kg/h) |

| 1 | THZ-X100 | 4 | 1.1 | 0.4-0.6 | 50-500 |

| 2 | THZ-X500 | 4 | 1.1 | 0.4-0.6 | 300-1000 |

| 3 | THZ×1000 | 7.5 | 1.1 | 0.4-0.6 | 750-1500 |

| 4 | THZ-X1500 | 11 | 2.2 | 0.4-0.6 | 1000-2500 |

| 5 | THZ-X2000 | 15 | 2.2 | 0.4-0.6 | 2000-3000 |

Related Products

Online Message