Complete project of glue mixing and batching system

Key words:

Category:

Product Description

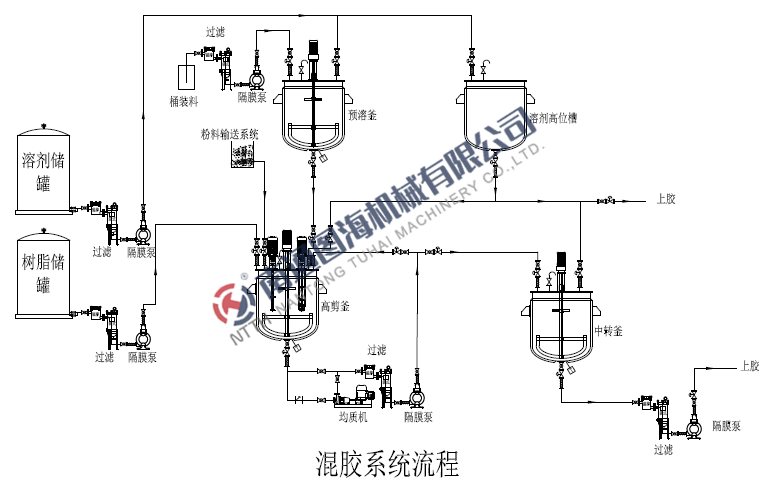

Introduction to the mixing system

In the current production process of front-end rubber mixing in the copper clad laminate industry, the ratio and mixing of raw materials is one of the main reasons affecting the quality of laminates. Our company's glue mixing system adopts automatic control scheme, relying on automatic procedures, to achieve the function of automatic proportioning of raw materials, conveying glue, and modulating finished rubber. At the same time, it is supplemented by a manual control system to achieve the effect of one backup and one use, that is, to improve the efficiency of production through the automatic control system, and to rely on manual methods to ensure stable production under abnormal conditions.

Functional features of the mixing system:

Temperature and level detection of tanks

Automatic control system of liquid level of rubber mixing kettle

Automatic weighing and metering control

It provides the drive and monitoring control of raw materials entering the corresponding storage tank

Automatic timing stirring and frequency conversion speed regulation control

Automatic proportioning control of process raw materials

All mixing operations can be done on the HMI

Record and history query of all mixing data

Design various reports according to user needs

Under normal working conditions, the system is fully automatic control

Manual control of the system during maintenance or special conditions

Cooperate with the production work of multiple gluing machines to complete the automatic control of material calling

Customer stories

|

|

|

|

|

|

|

|

Related Products

Online Message