Exhaust gas incinerator

Key words:

Category:

Product Description

Overall introduction of equipment:

The equipment, also known as waste gas incinerator, is widely used to solve the waste gas generated by vertical and horizontal gluing units in the coating industry and to recover heat. The whole machine equipment is mainly divided into three blocks: (1) high-temperature pyrolysis system; (2) Waste heat recovery system; (3) Fully automatic control system. The equipment has outstanding characteristics such as good treatment effect, fast heating speed and extremely low energy consumption.

Process principle and flow:

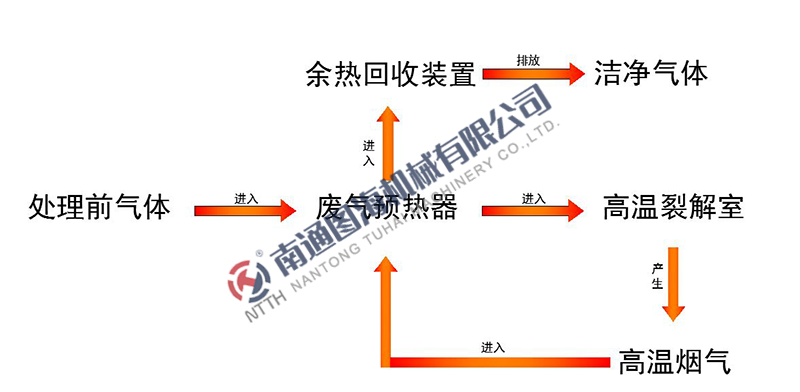

Regenerative organic waste gas cracking furnace is the use of gas direct combustion heating pyrolysis organic waste gas, pyrolysis treatment under the action of high temperature (850 °C), cracking chamber built-in ceramic heat storage body, used to store the heat generated by combustion, after reaching a certain temperature and then heating can automatically crack organic waste gas, greatly reducing the energy consumption of natural gas. The high-temperature flue gas generated after pyrolysis treatment preheats the organic waste gas before combustion through the exhaust gas preheating device, which is conducive to full combustion after the waste gas enters the pyrolysis chamber and improves the combustion efficiency. In addition to the exhaust gas preheater, the waste heat recovery device also involves multiple heat recovery chambers, including hot air chamber, hot oil chamber and hot water chamber, which can make full use of the heat generated by exhaust gas combustion and prevent energy waste.

Technical features:

1. It has a very high waste gas treatment efficiency, which can reach more than 99%.

2. Using advanced heat storage and heat exchange technology, energy consumption is greatly reduced.

3. Control the operation of the equipment through the automatic control system, monitor the operation status of the equipment in real time, and introduce the human-computer interaction interface to make the operation simpler, safer, more convenient and reliable.

4. Compact structure design, integrated design, greatly reducing floor space.

5. The residual heat after combustion is recovered to prevent energy waste.

6. Replaceable design of internal components, greatly prolonging service life.

Range of use:

It covers automobile manufacturing, machinery manufacturing, electronic manufacturing, electrical manufacturing, metallurgical steel industry, chemical industry and other industries that need to treat organic waste gas.

Related Products

Online Message