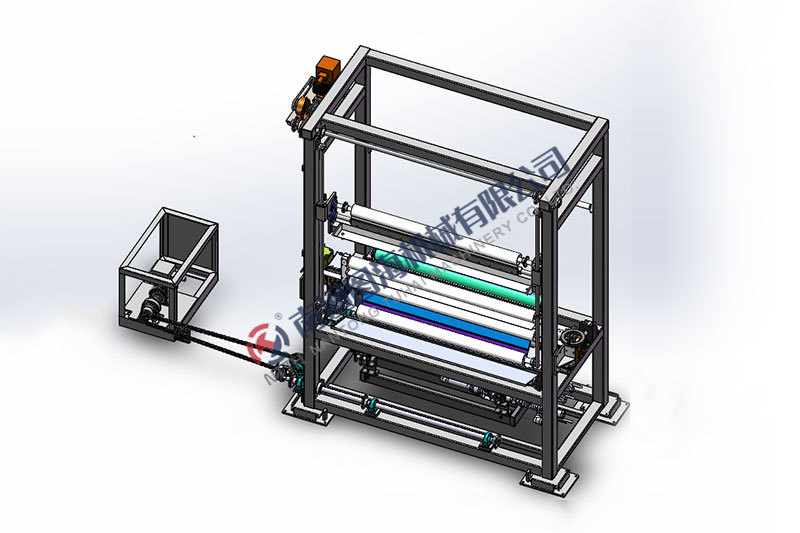

Impregnation machine

Key words:

Category:

Product Description

01 Application areas

Printed circuit boards, multilayer board substrates, PCB substrates

02Product features

1. Function introduction

The impregnation treatment of the substrate is divided into three stages, pre-wetting device, impregnation device and metering device, the pre-wetting device with a pre-wet roller first epoxy resin, pre-wetting the surface of the substrate, the substrate after pre-wet coating, and then immersion in the resin disc, saturated with immersion and then measurement, with two measuring rollers to scrape off the excess resin, complete the entire impregnation processing procedure. The two metering rollers adjust the gap between the two rollers with a master-slave gap adjustment system, and adjust the thickness of the impregnated resin of the impregnated substrate to facilitate operation. The other metering roller can be opened by the pneumatic cylinder to facilitate the substrate to pass through, and the pressure valve can be relieved when the cloth head passes through the gap, so that the cloth head passes through the gap, and then pressurized measurement, and the metering roller is driven by a motor through the belt. After the metering roller is measured, the residual resin on the metering roller is scraped off with a scraper, collected by the collection tray, and transferred to the viscosity mixing tank for continued use, and the rubber conveying pipeline containing the immersion tank is specially designed to reduce turbulence and bubbles. In the impregnation bath, all guide rollers touch the same side of the substrate to ensure the immersion effect

2. Equipment composition

01 Pre-impregnation machine composition

1. The scraping film adopts stainless steel sheet, which can be moved left and right.

2. It can be applied on one side and dipped on both sides, can be reversed and can be adjusted independently; There are three ways to wear pre-impregnation

3. Chain lifting mechanism and can remove the rubber tank for cleaning.

4. The impregnated part is equipped with chain lifting system,

02 Main immersion machine composition

1. It is composed of three parts: dipping, extrusion (measurement) and scraping.

2. The metering roller adopts high-brightness mirror roller, and the metering roller is φ240mm; And equipped with imported precision bearing group, active extrusion, can be forward and reverse rotation independent adjustment.

3. The gap adjustment of the metering roller adopts motor drive, which can be linked or single action left and right, and can display the gap between the two ends of the metering roller.

4. SUS304 plate sandwich tank design, the tank can be connected to hot water, the bottom multi-point glue.

5. The rubber tank and the frame are detachable, and the chain is raised and lowered to facilitate the tank to move out for cleaning.

6. Glue tank glue circulation piping + glue pumping pump group + bag filter barrel

03. Technical parameters

1. Applicable substrate: glass fiber cloth 1017, 1027, 1037, 1061080, 2116, 7628

2. Substrate tension 30 to 50kg

3. Fluctuation <± 4N after tension control

4. Prepreg roller machine power 2 hp

5. Metering roller machine power 3 horsepower

6. The thickness of the surface plating of the metering roller is not less than 0.2mm, the surface hardness is greater than HV700, the surface roughness is not less than Ra0.1, and the dynamic balance accuracy grade is not less than G2.5

Related Products

Online Message